Posted in Blog, Innovation, Strategy by Jo North

Understanding TRLs

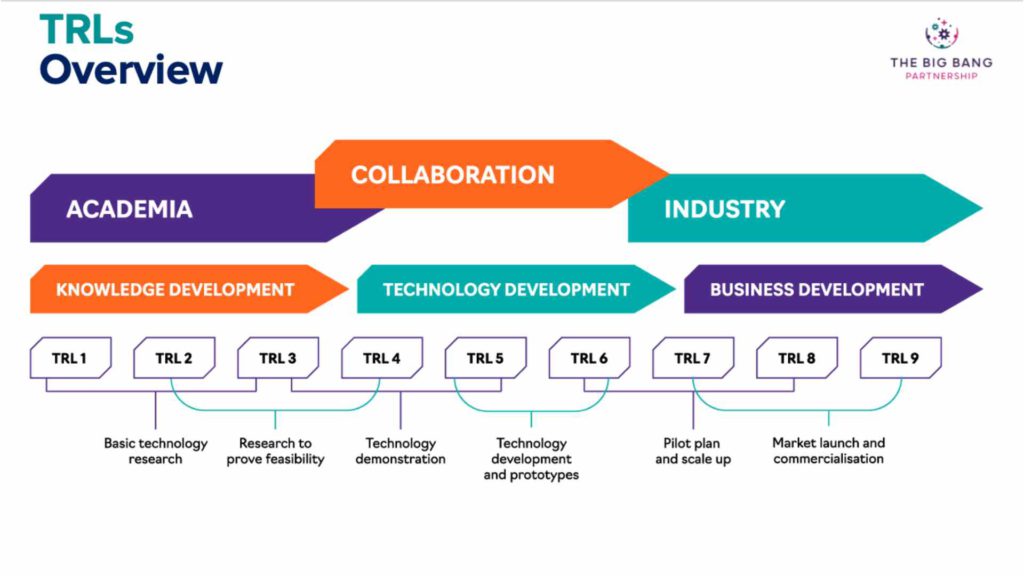

TRLs is short for “Technology Readiness Levels”. They are a type of measurement system used in innovation development to assess the maturity level of a particular technology. Originally developed by NASA in the 1970s, TRLs provide a scale from 1 to 9 to indicate the progress of a technology from initial concept (TRL 1) to a fully operational system (TRL 9). The TRL scale provides a common language for stakeholders to discuss the development process of a technology, from basic research to final deployment.

TRLs offer a standardized method for assessing technology maturity, aiding stakeholders in making informed decisions about funding, development, and commercialization. By adopting TRLs, countries and sectors worldwide can effectively manage the innovation process, ensuring that new technologies are ready for market and operational use.

TRLs: Importance for Innovators

TRLs are important for innovators because they offer a clear pathway for technology development. By understanding and utilizing TRLs, innovators can:

- Track progress: Identify the current stage of their technology and plan the next steps.

- Mitigate risks: Spot potential challenges early and address them proactively.

- Improve communication: Clearly convey the technology’s development stage to stakeholders.

TRLs: Benefits to Other Stakeholders

TRLs offer a transparent and structured approach for the development and commercialization of new technologies. This framework ensures that all involved parties can effectively contribute to and benefit from the innovation process, because TRLs provide valuable insights to various stakeholders. They help each stakeholder group to do the following:

Grant Funders and Investors

- Evaluate viability: Assess the maturity and potential of technologies before committing resources.

- Inform decisions: Make informed investment or funding decisions based on the technology’s readiness.

Researchers

- Guide research: Align research activities with the required TRL to advance technology development.

- Collaborate effectively: Coordinate with industry partners by understanding their TRL expectations.

End Users

- Expectation management: Understand the maturity of technologies and set realistic expectations for deployment.

- Adoption readiness: Plan for the integration and usage of new technologies based on their readiness levels.

Sectors and Countries Using TRLs

Global Adoption of TRLs

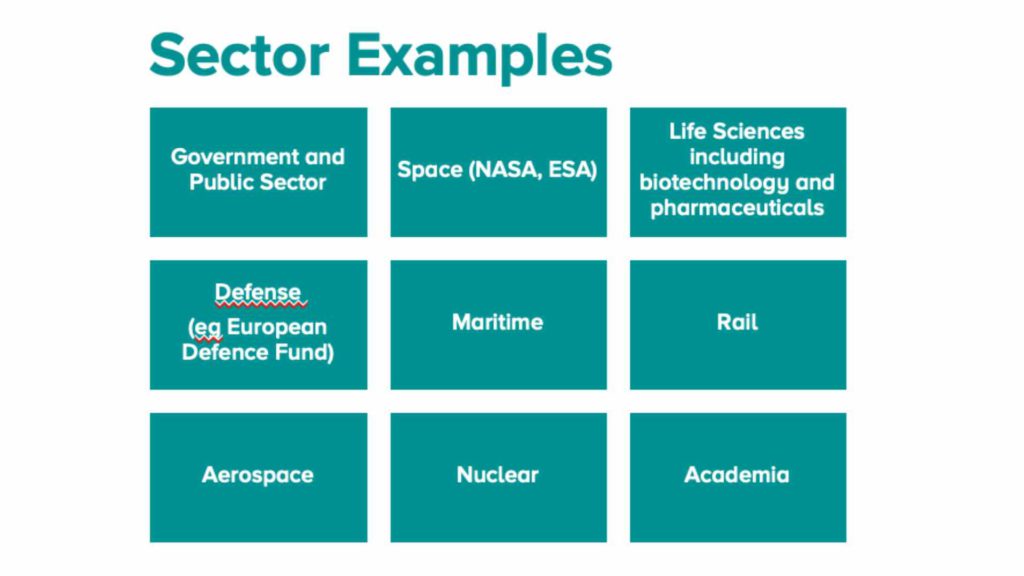

Technology Readiness Levels (TRLs) are used worldwide across various sectors to assess and manage the maturity of technologies. Here are some key sectors and regions where TRLs are used.

Sectors

Space and Aerospace

NASA originally developed the TRL framework, and it continues to be extensively used in space and aerospace industries. The European Space Agency (ESA) and other space agencies globally have adopted TRLs to evaluate the readiness of technologies for missions and commercial space projects (Wikipedia) (Zabala Innovation).

Life Sciences

The life sciences sector, including biotechnology and pharmaceuticals, utilizes TRLs to manage the development of new medical devices, drugs, and diagnostic tools. Companies and research institutions use TRLs to align project milestones with technological maturity, ensuring that innovations are market-ready and safe for public use (Plexus).

Defense

Governments and defense organizations use TRLs to develop advanced military technologies. The European Defence Fund (EDF), for example, employs TRLs to manage the development and deployment of new defense systems and equipment, supporting projects that range from unmanned vehicles to next-generation defense systems (Defence Industry and Space).

Countries

United States

The U.S. Department of Defense (DoD) extensively uses TRLs to evaluate the maturity of technologies in defense projects. Additionally, TRLs are integral to projects funded by agencies such as NASA and the National Institutes of Health (NIH), which supports life sciences and medical research initiatives (Homepage | Defensebridge).

European Union

The EU (European Union) incorporates TRLs in its Horizon Europe framework, a funding program that supports research and innovation across member states. The European Space Agency also uses TRLs to manage space technology projects. The European Defence Fund allocates substantial resources to projects evaluated through the TRL framework, ensuring technologies meet readiness criteria before deployment (EMDESK) (Defence Industry and Space).

Australia

In Australia, TRLs are used by research institutions and industries involved in innovation, such as the University of Sydney, which integrates TRLs into its commercialization strategies for new technologies. This helps bridge the gap between research and market deployment (Wikipedia).

TRLs in the UK: Adoption Across Sectors

In the United Kingdom, Technology Readiness Levels (TRLs) are widely used across various sectors to evaluate the maturity of new technologies and guide investment decisions. Examples of usage of TRLs in different sectors in the UK are:

Government and Public Sector

The UK government extensively uses TRLs to assess and fund technology projects. Agencies such as UK Research and Innovation (UKRI) and the Science and Technology Facilities Council (STFC) incorporate TRLs in their funding criteria to ensure projects are at the appropriate stage of development before receiving financial support. This approach helps streamline the allocation of resources and enhance the impact of public investments in innovation (GOV.UK) (UK Research and Innovation) (UK Research and Innovation).

Nuclear Industry

The Nuclear Decommissioning Authority (NDA) in the UK uses TRLs to evaluate technologies for safe and efficient decommissioning processes. This ensures that technologies are mature enough to be deployed on-site, reducing risks associated with nuclear decommissioning activities. The NDA’s guidance on TRLs helps maintain consistency and safety standards across the sector (GOV.UK).

Aerospace and Defense

TRLs are important in the UK’s aerospace and defense sectors, where organizations such as BAE Systems and Rolls-Royce use them to assess the readiness of new technologies. This helps manage risks and align technological developments with strategic defense objectives. The European Defence Fund (EDF) also supports UK companies in developing interoperable defense technologies using TRL assessments (Ayming UK) (Joining Innovation with Expertise).

Academic and Research Institutions

UK universities and research institutions apply TRLs to bridge the gap between academic research and commercial applications. By tracking the maturity of their innovations, these institutions can better plan the transition from research to market-ready products. This approach is particularly evident in collaborations funded by Innovate UK, which supports projects across various TRL stages (UK Research and Innovation) (Joining Innovation with Expertise).

Detailed Breakdown of TRLs

Understanding and accurately determining the TRL of a technology helps manage development and communicate maturity to stakeholders. By following the detailed criteria for each TRL stage, innovators can effectively track progress, mitigate risks, and plan necessary steps to bring technology to market

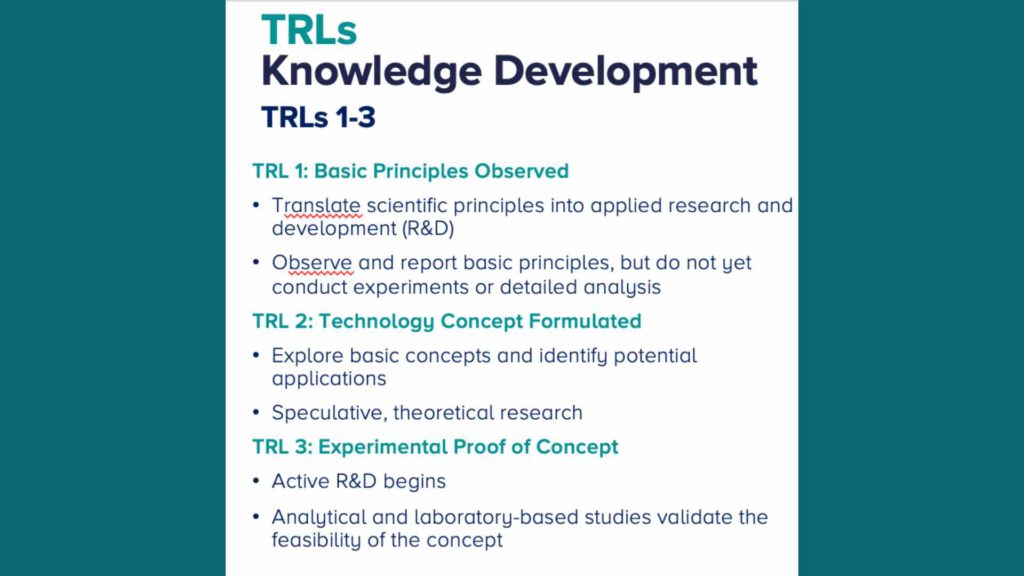

TRL 1: Basic Principles Observed

At TRL 1, researchers translate scientific principles into applied research and development (R&D). They observe and report basic principles, but do not yet conduct experiments or detailed analysis.

Criteria:

- Observed and reported basic scientific principles.

- No practical application envisioned.

TRL 2: Technology Concept Formulated

At TRL 2, researchers explore basic concepts and identify potential applications. This stage involves speculative, theoretical research without experimental evidence.

Criteria:

- Proposed basic principles for practical applications.

- Formed hypotheses based on initial observations.

TRL 3: Experimental Proof of Concept

In TRL 3, active R&D begins. Analytical and laboratory-based studies validate the feasibility of the technology concept.

Criteria:

- Demonstrated initial proof of concept through analytical and experimental work.

- Integrated basic technological components to verify they work together.

TRL 4: Technology Validated in Lab

At TRL 4, researchers integrate basic technological components to establish their compatibility. Validation occurs in a laboratory environment.

Criteria:

- Tested components in a laboratory to validate performance and feasibility.

- Integrated basic technological components.

TRL 5: Technology Validated in Relevant Environment

In TRL 5, testing moves beyond the lab to a relevant environment. Researchers use a higher fidelity prototype compared to TRL 4.

Criteria:

- Integrated components with realistic supporting elements to demonstrate performance in a simulated operational environment.

- Conducted testing in an environment simulating real-world conditions.

TRL 6: Technology Demonstrated in Relevant Environment

TRL 6 involves demonstrating a prototype system in an environment closely resembling the intended operational setting.

Criteria:

- Demonstrated a system/subsystem model or prototype in a relevant environment.

- Demonstrated a nearly complete system with an operational environment interface.

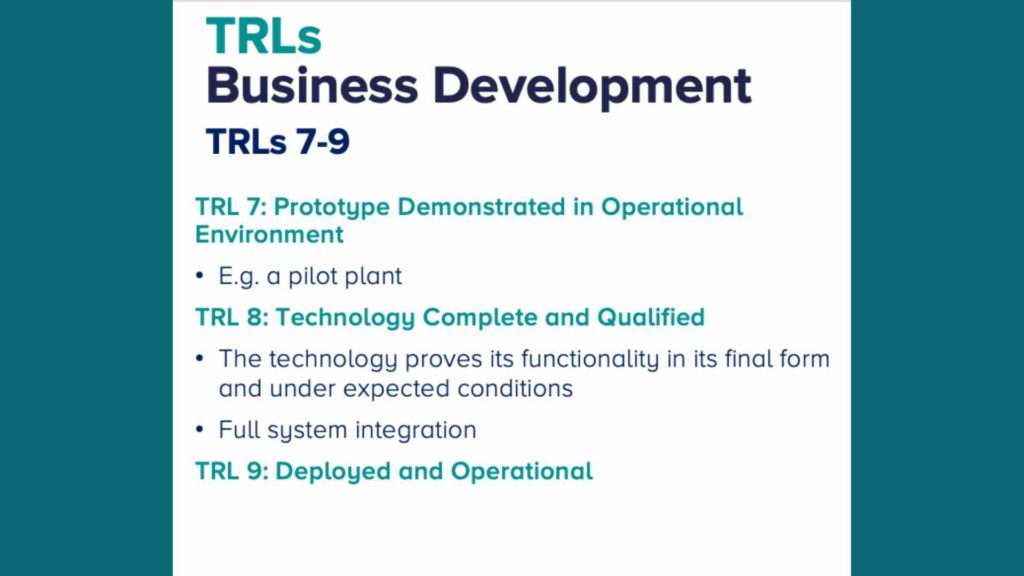

TRL 7: System Prototype Demonstration in Operational Environment

In TRL 7, a system prototype undergoes demonstration in an operational environment. Researchers integrate all system components at this stage.

Criteria:

- Developed a prototype near the planned operational system.

- Demonstrated the prototype in an operational environment, such as a pilot plant.

TRL 8: System Complete and Qualified

At TRL 8, the technology proves its functionality in its final form and under expected conditions. This phase involves end-to-end system testing and validation in an operational environment.

Criteria:

- Tested and validated the technology in its final form under expected conditions.

- Achieved full system integration.

TRL 9: Actual System Proven in Operational Environment

At TRL 9, the actual system, tested and qualified, operates in the intended environment. The technology reaches readiness for full-scale deployment.

Criteria:

- Successfully tested and proven the actual system in an operational environment.

- Deployed and operational system.

Using the TRL Criteria

To determine the TRL of an innovation, follow these steps:

- Define the Technology: Clearly describe the innovation and its intended application.

- Evaluate Against TRL Criteria: Compare the innovation’s current status with the detailed criteria for each TRL stage.

- Assess Experimental Data: Examine any existing experimental data, prototypes, and testing environments.

- Identify Gaps: Determine what is missing to reach the next TRL level, including additional testing, integration, or validation steps.

- Document Findings: Keep thorough records of the innovation’s progress through the TRL stages, including experimental results and validation tests.

Actions to Progress Innovations Through TRLs

Progressing innovations through TRLs requires a systematic approach, clear objectives, and continuous feedback. By following these steps, researchers and businesses can effectively advance their technologies from basic principles to fully operational systems, ready for market deployment.

TRL 1 to TRL 2: From Basic Principles to Concept Formulation

Define the Problem: Identify and articulate the specific problem or challenge the technology aims to address. Clear problem statements guide focused research.

Literature Review: Conduct a comprehensive review of existing literature. This helps build a foundation for understanding the current state of technology and identifying gaps.

Initial Hypothesis: Formulate hypotheses based on observed principles. This guides early experimental designs and conceptual work.

TRL 2 to TRL 3: From Concept Formulation to Proof of Concept

Preliminary Modeling: Develop theoretical models to predict the behavior of the technology. Use simulations to validate these models.

Experimental Setup: Design and conduct small-scale experiments to test the hypotheses. Use controlled environments to isolate variables and gather initial data.

Data Analysis: Analyze experimental data to confirm or refute the initial hypotheses. Document findings and adjust models as necessary.

TRL 3 to TRL 4: From Proof of Concept to Lab Validation

Prototype Development: Build a basic prototype of the technology. Focus on core functionalities to test the essential components.

Lab Testing: Perform rigorous testing of the prototype in a laboratory setting. Measure performance against predefined benchmarks.

Iterative Refinement: Refine the prototype based on test results. Implement changes and re-test to ensure improvements.

TRL 4 to TRL 5: From Lab Validation to Relevant Environment Testing

Enhanced Prototyping: Develop a more advanced prototype that includes additional features. Ensure the prototype can operate in conditions similar to the intended operational environment.

Simulated Environment Testing: Test the advanced prototype in a simulated environment that closely mimics real-world conditions. Identify any operational issues and address them.

Stakeholder Feedback: Engage with stakeholders (e.g., potential users, industry experts) to gather feedback on the prototype’s performance and applicability.

TRL 5 to TRL 6: From Relevant Environment Testing to Demonstration

Field Testing: Conduct field tests in environments that closely resemble the actual operational conditions. Monitor the prototype’s performance under real-world stressors.

Performance Metrics: Establish clear metrics to evaluate the prototype’s performance. Compare these metrics against industry standards and user expectations.

Technical Documentation: Document all aspects of the prototype’s performance, including successes and areas needing improvement. Use this documentation to support further development.

TRL 6 to TRL 7: From Demonstration to Operational Environment

Full System Integration: Integrate the technology with other systems to ensure compatibility and functionality. This includes hardware, software, and operational processes.

Operational Testing: Test the fully integrated system in an operational environment. Identify any integration issues and resolve them promptly.

Regulatory Compliance: Ensure the technology meets all regulatory requirements for its intended use. This may involve obtaining certifications or approvals from relevant authorities.

TRL 7 to TRL 8: From Operational Environment to Complete System

User Training: Provide training for end-users to ensure they can effectively operate the technology. Develop user manuals and support materials.

Pilot Programs: Implement pilot programs to test the technology in real-world scenarios. Collect data on performance, usability, and user satisfaction.

Feedback Loop: Create a feedback loop with users to gather insights and suggestions. Use this feedback to make final adjustments to the technology.

TRL 8 to TRL 9: From Complete System to Proven System

Full Deployment: Deploy the technology in its intended operational environment. Monitor its performance continuously to ensure it meets all expectations.

Performance Monitoring: Establish a system for ongoing performance monitoring and maintenance. Address any issues that arise promptly to maintain operational integrity.

Market Launch: Launch the technology in the market. Develop marketing strategies to promote the technology and educate potential users about its benefits.

Technology Readiness Levels Example: Offshore Wind Sector

The offshore wind industry spans multiple Technology Readiness Levels, from experimental floating turbines to commercially successful fixed-bottom systems. Each stage involves rigorous testing and validation to ensure safety, reliability, and efficiency. The continuous development and deployment of these technologies are crucial for expanding offshore wind capacity and contributing to global renewable energy goals (MDPI) (IRENA).

Early-Stage Technology: Floating Wind Turbines

TRL 3-4

Floating wind turbines are in the experimental and prototype stages. They aim to enable wind power in deeper waters, where traditional fixed-bottom turbines are not feasible. Projects like WindFloat Atlantic are testing these technologies in real-world conditions. Floating turbines face challenges like stability and anchoring in deep-sea environments. The success of these prototypes could open vast new areas for wind energy production (MDPI) (IRENA).

Mid-Stage Technology: Advanced Turbine Foundations

TRL 5-6

Advanced turbine foundations, such as suction caissons and jackets, are moving through pilot and demonstration phases. (Suction caissons are a type of foundation used in offshore engineering, particularly for wind turbines and oil platforms. They are large, hollow, cylindrical structures that are open at the bottom and closed at the top). These foundations are crucial for stabilizing turbines in varied seabed conditions. The physical modeling and validation of these designs are ongoing to ensure reliability and cost-effectiveness. For example, suction caissons have shown promise in reducing installation costs and environmental impact (MDPI).

Late-Stage Technology: High Voltage Direct Current (HVDC) Transmission

TRL 7-8

HVDC transmission systems are nearing full-scale deployment. These systems are essential for efficiently transmitting electricity from offshore wind farms to onshore grids over long distances. They minimize power losses compared to traditional HVAC systems. The integration of HVDC technology in large offshore projects, such as those in the North Sea, demonstrates its maturity and readiness for widespread use (MDPI) (IRENA).

Commercial Technology: Fixed-Bottom Turbines

TRL 9

Fixed-bottom wind turbines, like monopiles and jackets, are fully commercialized and widely used in offshore wind farms. These technologies have proven reliability and performance in various marine environments. Projects across Europe and Asia have established these foundations as the standard for offshore wind, providing a solid base for the turbines and ensuring stability even in harsh conditions (MDPI) (IRENA).

Round Up

Technology Readiness Levels (TRLs) offer a type of measurement system to assess the maturity level of a particular technology, ranging from the lowest level of technology readiness (TRL 1) to the most mature technology (TRL 9). Researchers begin with basic research, observing basic properties and conducting scientific research to establish initial findings. Through laboratory studies and analytical studies, they validate concepts and make analytical predictions about the technology’s potential. As they progress through the TRL scale, they use TRL definitions to guide the development process, moving from low fidelity prototypes to more advanced system models.

Active research involves rigorous testing and data collection to meet design specifications and technology requirements. Clinical trials and clinical studies evaluate the technology’s impact and effectiveness, especially in pharmaceuticals and medical devices. Demonstration of an actual system prototype and operational tests in relevant environments mark significant milestones in development programs.

The use of TRLs provides a common language for stakeholders, facilitating technology readiness assessment and helping secure government funding and government grants. This approach ensures that technology projects meet critical components and critical areas of development. Industry sectors like space exploration technologies and software development benefit from the TRL system, which helps in the innovation journey and achieving regulatory approvals.

By understanding the technical maturity of a technology on a case-by-case basis, researchers can plan future research, meet technology capabilities, and achieve the final configuration for market deployment.